“This was not a ‘spec house’ but one that has a unique personality and footprint. The purposes of this undertaking were to produce a natural, attractive home, provide labor opportunities on the reservation and instill pride of ownership within a community-directed operation.” –Richard Flatau

Cordwood Home on the White Earth Reservation in Minnesota.

Making Contact

The MMCDC (Midwest Minnesota Community Development Corporation) contacted us with regard to the possibility of building a cordwood home on the White Earth Reservation in NW Minnesota. The idea was to provide attractive, affordable, energy efficient housing on the reservation while offering employment opportunities for the training of tribal cordwood masons.

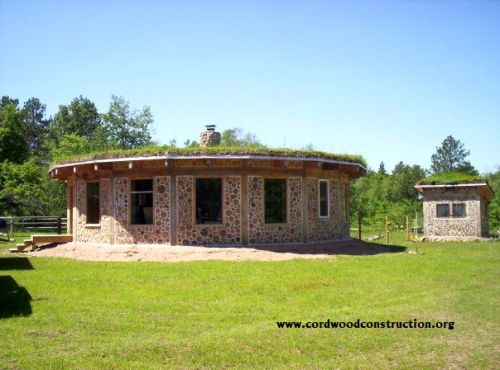

The plan to work with the White Earth Tribal Land Office allowed the home to be constructed on Tribal Trust Land. The local contractor and members of the tribe were enthusiastic about building a home that would be in harmony with the natural surroundings, be energy efficient and use locally available resources. It would be designed and built with wood from the area and in accord with Ojibwa home traditions. That is, the house would be a multi-generational home, it would incorporate a large family gathering area, the entrance would face east, and it would be comprised mostly of renewable materials.  Floor plan for 1840 sq. ft. home (1,040 sq. ft. first floor, 800 sq. ft. second floor).

Floor plan for 1840 sq. ft. home (1,040 sq. ft. first floor, 800 sq. ft. second floor).

Vision

Here are the processes and attributes of this very successful home building project.

- Efficient design with owner input (Ojibwa Tribal member) leading to functional space usage

- 12/12 pitch roof for an additional 800 sq. ft. adding 2 bedrooms, and a bath upstairs

- Insulated sand bed with radiant-in-floor heat (coupled with off-peak power usage)

- Northern White Cedar post and beam framework (a sacred tree in Ojibwa culture)

- 16″ Northern White Cedar cordwood log ends

- High R-value foam insulation in center cavity (R-30)

- Cold weather mortaring techniques

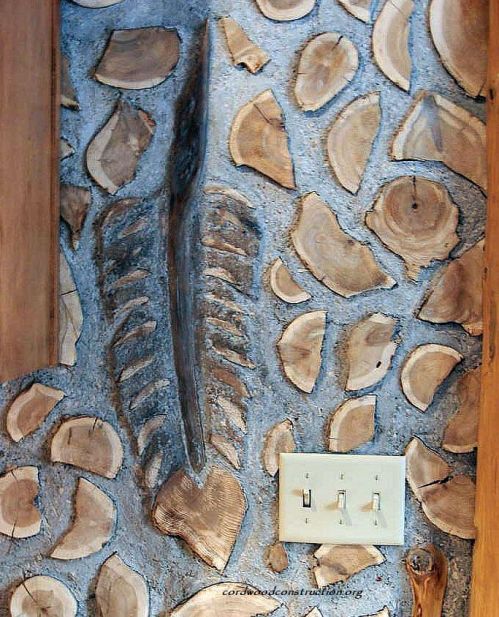

- Ojibwa design features mortared into the cordwood walls

- Ojibwa mortaring crews hired

Good People

We were fortunate to work with two very capable builders: Robert Zahorski, the general contractor and Bill Paulson, a tribal member who was the project coordinator. Each dovetailed into the other’s strengths and the result was a building that evokes Ojibwa traditions, built with 21st-century construction techniques.

Sand bed for heat storage

In the fall of 2009 the foundation was built with an insulated sand bed, beneath an insulated cement slab. This sand bed will store heat during off-peak energy hours and then radiate it throughout the house during the high-energy-rate use daylight hours. This is similar to radiant-in-floor heat, except the large sand bed under the foundation is insulated and provides heat energy storage for the home. The drawing on the left, courtesy of Alan Stankevitz of daycreek.com, gives a rendering of this concept.

Cedar post and beam framework

The post and beam framework was erected by a local contractor. Cedar posts gathered from near the reservation were milled on the two sides that would abut the cordwood infill. They were left rounded on the interior and exterior.

The cedar post and beam framework was braced. The bracing is very important to maintain structural integrity and prevent sections from going “out of square.” The braces are only removed after the cordwood walls approach the four-foot mark. As you will notice, the roof is complete and shingled. Having the roof finished before cordwood construction begins means that the cordwood mortaring can take place, for the most part, out of the elements. If a section is not finished in time, it can be ‘boarded up’ for the winter and work can continue on the inside of the building. Attaching tarps to the fascia boards is helpful when it is necessary to protect the mortar and the workers from the drying rays of the sun.

Electrical

There are many code compliant ways to run electrical wiring in a cordwood building. In general for wiring jobs, we recommend that you follow your local building codes. In cordwood buildings in various parts of the country, we have used conduit, Romex NM, and UL 12-2 wiring (with a resistant coated jacket) wire-stapled to the middle of the posts. In this particular instance, the electrical contractor chose to run flexible, plastic tubes (also called flexible PVC conduit). In accord with the blueprint, the ‘blue smurf’ wiring tubes were then installed throughout the building.  The hanging blue tubes (with metal receptacles) were very irritating to work around during construction. The masons were constantly bumping into them while mortaring.

The hanging blue tubes (with metal receptacles) were very irritating to work around during construction. The masons were constantly bumping into them while mortaring.

Window Boxes

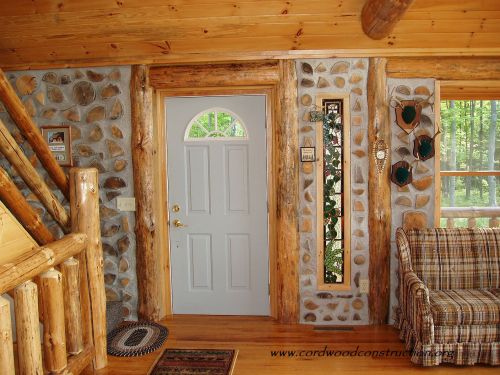

The window boxes (made of double 2″ x 8″s) were hung, using the sturdy top plates as fastening points. The two exterior door frames were ‘roughed in.’ Later these would have doors with beautifully etched glass panels installed for both privacy and beauty (see picture at end of article).

The window boxes, door framing and wiring tubes are shown in the phot0. Notice that the window boxes are screwed into the top plate of the post and beam framework. This helps to assure that the windows will always open.

The window boxes, door framing and wiring tubes are shown in the phot0. Notice that the window boxes are screwed into the top plate of the post and beam framework. This helps to assure that the windows will always open.

Cedar Log Ends

Early in the process, the decision was made to use 16″ cedar log ends for the cordwood infill. This length would provide an insulation value of R-24. The logs had been cut and dried for four years in eight-foot lengths. After that, they were cut into 16″ lengths and 70% of the logs were split to assure faster drying.

On the way to being stacked the logs were dipped in a borate solution (four cups of borax to one gallon of water). Finally, the logs were stacked in single rows for drying. While stacked, the exterior ends of the log ends were brushed with a UV blocker (Lifeline Exterior from Permachink) so that the faces of the exterior log ends would maintain their color. The interior log end faces were left natural.

Mortar Mixing

A mortar mixer was purchased and three different individuals were trained on mixing proper cordwood “mud.” It was very helpful to have an alternate “mortar mixer” when someone had a scheduling conflict.

The mortar mixture used was the Flatau’s favorite mix of:

- 1 part Portland Cement

- 1 part Hydrated Lime Type S

- 2 parts soaked softwood sawdust (coarse)

- 3 parts washed, coarse sand

The overall feel of the mortar is an adobe style texture which is easily tuck-pointed with a spoon.

Injecting Foam Insulation

For insulation, the initial strategy was to use regular coarse softwood sawdust mixed with hydrated lime in the center cavity, but a dearth of coarse, softwood sawdust in the area, led to another decision. It was determined that injected closed cell foam was going to be used. The main advantages of injected foam are: high R-value (R-7 per inch), it bonds well with the wood and tends to fill every nook and cranny. Cordwood builder Sandy Clidaras of Quebec has been a pioneer in using closed cell foam in single wall cordwood and so we consulted him for advice. Sandy generously gave of his time and information. Convinced of the foam’s merits, we ordered eight kits of foam insulation.

When using injected closed cell foam the cordwood wall is first built in two-foot-high sections. Half-inch tubes are inserted in the center cavity as the wall is being built. The mortar is left to harden for at least 24 hours (any sooner and the wall may be lifted by the pressure of the expanding foam). The foam is then injected into the tubes. The foam comes in two canisters, which must be warmed before being used and then shaken while injecting (this makes certain all the foam is used). There are many companies that make expanding foam and quite a number of building supply stores carry the kits. To find a foam retailer, do a Google search and make a few phone calls to get your best price. On a 1,200 square foot home, with eight-foot high cordwood walls, the foam will add approximately $4000 to the cost of construction.

The closed cell foam is rated at an R-value of 7 per inch. A 5-inch cavity gives an R-value of 35. Coupled with the usual 16″ cordwood walls’ R-value of R-24, we extrapolated that our wall R-value approached R-30.

Cold Weather Mortaring

When we left to conduct another workshop in North Carolina the cordwood mortaring crew was about one-third finished. Little did we know at the time that the fall of 2009 in northwestern Minnesota would turn into one of the coldest on record. Finishing the cordwood infill in October meant tarping the house, covering the cordwood walls with blankets and ‘firing-up’ a propane heater. Starting a little later in the morning allowed the temperatures to rise a bit.

If at all possible, cold weather mortaring is something to avoid. If the water in the mortar mix freezes it can cause the mortar to flake and crumble. Since this home was built within a post and beam framework there was no worry about structural integrity, but to have to re-mortar a complete wall or part of a wall would become a very labor intensive operation, especially since the mortar flaking may not be immediately apparent.

If you must mortar in cold weather, it is imperative to finish all mortaring before freezing temperatures occur. If this becomes impossible, then precautions need to be taken to assure the mortar will not freeze:

- The freshly mortared cordwood wall must be covered with blankets or tarps and secured, so it is protected from freezing cold and wind.

- If there is a crew working on different sections (as was the case on this project) wrap the entire building with tarps to cover the work. (see picture)

- Even though there is a little heat generated from the chemical reaction of the Portland cement and the water, it is not enough to prevent it from freezing when the temperatures plummet.

- On this project, not only did we tarp the entire house, but we placed a propane heater in the middle of the house to keep the mortar from freezing.

- It is very important to keep the walls covered, except when mortaring, for at least seven days.

- According to masonry experts, masonry mortar takes seven days to dry and fourteen days to cure.

There are ingredients that can be added to the mortar mix to retard freezing (calcium chloride), but with the soaked sawdust in this mix, no one can adequately be certain that these non-freeze agents will work properly. So it is best to cover, seal and provide a source of heat if the temperature is going into the 20’s. Diminishing the amount of sawdust as temperatures drop can be helpful, as the retarding feature of the sawdust is less important. On this project, we were properly prepared to prevent the masonry from freezing during the very cold month of October.

| While the precautions kept the cordwood walls from freezing, it added to labor costs by requiring time-consuming ‘take-down’ every morning and ‘button-up’ in the evening. The cordwood masonry was finished by late October and the inside work commenced. The entire cordwood infill was accomplished in less than six weeks. |

Native Cordwood Masons

One of the highlights of this project was meeting and teaching the cordwood mortaring group which had been assembled for this task. The crew was paid a good wage and learned valuable masonry and construction skills in the process. They were enthusiastic and learned quickly. As the project went along, some of the guys started talking about building an Ojibwa Ceremonial Lodge and personal homes, using the abundant Tamarack on the edges of the surrounding wild rice lakes. One of the many side benefits of being involved in this project was receiving gifts of hand harvested and processed wild rice. Even though the project was open to women applicants, there were no takers. Becky ended up being the only woman on the crew and enjoyed working with the guys.

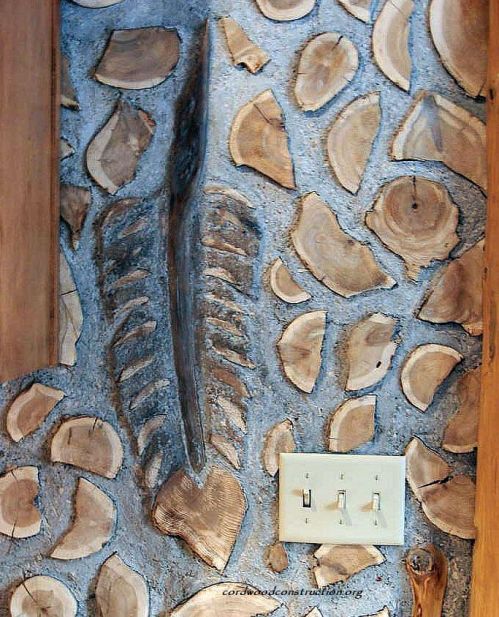

Special Effects

Bill and Robert were instrumental in making some of the artistic Ojibwa motifs in the White Earth Home. The owner of the home was a member of the Bear Clan, so Bill decided he would put a bear paw, a feather, the Medicine Wheel and shelves in the cordwood wall. They became the focal points of the house.  We visited the home a year after completion to do any weatherizing that might be required We applied Permachinktm around a few log ends that had loosened and stuffed a few round log ends that had checked with white fiberglass. This well constructed home is easy to heat and blends beautifully into the surrounding woodland.

We visited the home a year after completion to do any weatherizing that might be required We applied Permachinktm around a few log ends that had loosened and stuffed a few round log ends that had checked with white fiberglass. This well constructed home is easy to heat and blends beautifully into the surrounding woodland.

The home has caused quite a stir in the surrounding area, and there are plans for building a commercial law office, a ceremonial lodge and more cordwood homes. We are proud of our involvement and grateful for the friendships made, but we are also thankful to the tribal members who welcomed us and provided insight and assistance in making this home come to fruition. Being involved in a project of this magnitude was certainly a peak experience for us.

(Below) Note the feather (left) and the Bear Paw (right) on either side of the door.

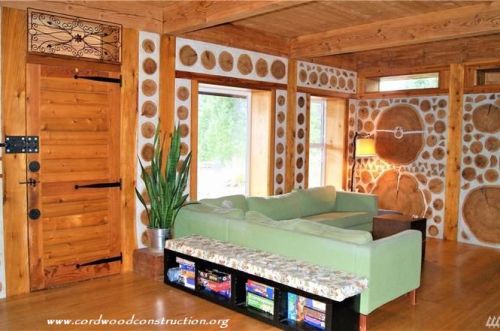

Winter or summer, the White Earth Cordwood home is comfortable and inviting to family and friends.

Winter or summer, the White Earth Cordwood home is comfortable and inviting to family and friends.

Should you wish to learn how to build a cordwood cottage, cabin or home, please visit www.cordwoodconstruction.org While you are there, click on the pictures, read the brief articles, check out the latest workshops and newsletter and if you are interested click on the Online Bookstore to see all the cordwood literature available in print and ebook format.

If you have questions that aren’t answered on the website you can email me at richardflatau@gmail.com

Readers have requested a brief bio, so here goes:

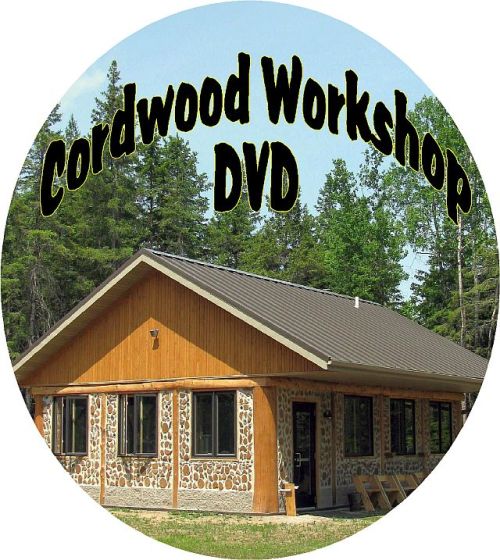

Richard & Becky Flatau built their mortgage-free cordwood home in 1979 in Merrill, Wisconsin. Since then, they have written books, conducted workshops, facilitated the 2005, 2011 and 2015 Cordwood Conferences and provided consultation for cordwood builders. Cordwood Workshop DVD (2018), Cordwood Construction Best Practices (print 2017) and Cordwood Conference Papers 2015 are the newest publications available from their Online Cordwood Bookstore. The books & DVD are also available as ebooks for a quick and easy shipping free download. www.cordwoodconstruction.org

This is the Cordwood Workshop Video will show you how to build a best practices cordwood home.

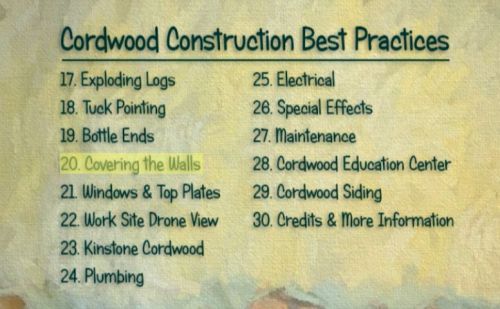

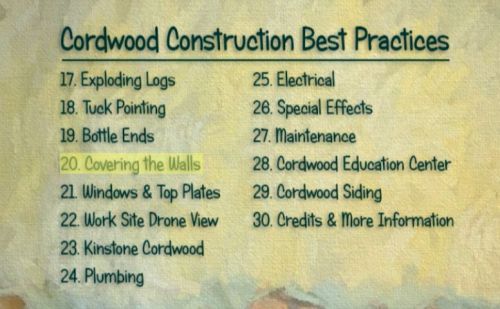

These are the 30 menu sections from the Cordwood Workshop DVD.

Thank you for your kind attention to Cordwood Construction. If you would like more information, please visit www.cordwoodconstruction.org

Or email me at richardflatau@gmail.com

Want to learn about the Top Ten Best Practices to make your building warm and energy efficient (or cool and energy efficient)?

Want to learn about the Top Ten Best Practices to make your building warm and energy efficient (or cool and energy efficient)?

![]() How about a cozy place by the fire?

How about a cozy place by the fire? Thinking about an Off-Grid cordwood cabin?

Thinking about an Off-Grid cordwood cabin?

Want to build a sauna that doubles as a guest cottage?

Want to build a sauna that doubles as a guest cottage?

How about a cordwood castle?

How about a cordwood castle?

Million dollar cordwood lodge.

Million dollar cordwood lodge. 16 sided cordwood home?

16 sided cordwood home?

Whatever your cordwood ideas; on this new site, you will find detailed information so you can proceed with confidence. Visit https://cordwoodconstruction.org to explore all your options.

Whatever your cordwood ideas; on this new site, you will find detailed information so you can proceed with confidence. Visit https://cordwoodconstruction.org to explore all your options.

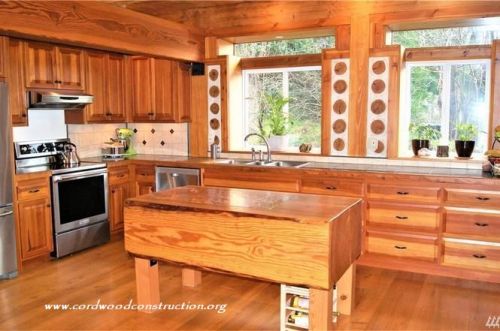

The kitchen at the Pratt’s home is a lovely place for a healthy meal.

The kitchen at the Pratt’s home is a lovely place for a healthy meal.

Double Wall with 4.3 KW array in LaCrescent, Minnesota by Alan Stankevitz.

Double Wall with 4.3 KW array in LaCrescent, Minnesota by Alan Stankevitz.

Nick Kautzer post frame and cordwood in California.

Nick Kautzer post frame and cordwood in California.

Washington State cordwood with Western Red Cedar.

Washington State cordwood with Western Red Cedar.

Vancouver Island cordwood home with a fish pond.

Vancouver Island cordwood home with a fish pond.

Spartanburg, South Carolina with a spiral staircase and a basement.

Spartanburg, South Carolina with a spiral staircase and a basement.

Asheville, North Carolina, cordwood on a mountain top.

Asheville, North Carolina, cordwood on a mountain top.

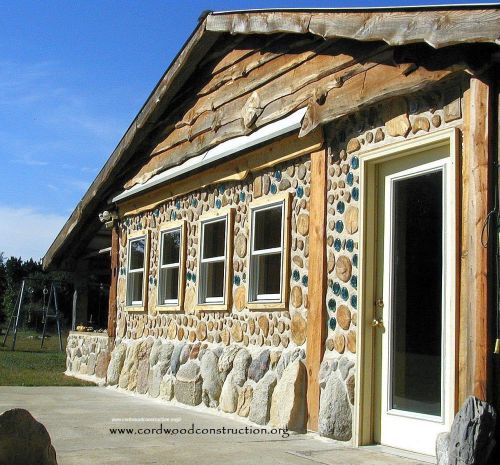

Cordwood home at White Earth in Minnesota made of cedar, with a room in the attic truss for an additional 800 sq. ft. of living space.

Cordwood home at White Earth in Minnesota made of cedar, with a room in the attic truss for an additional 800 sq. ft. of living space.

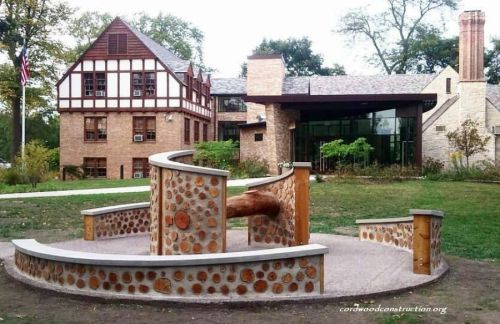

The Cordwood Education Center Classroom in Merrill, Wisconsin.

The Cordwood Education Center Classroom in Merrill, Wisconsin.

Flatau’s Chateau lovely cordwood home in Merrill, Wisconsin (above and below).

Flatau’s Chateau lovely cordwood home in Merrill, Wisconsin (above and below).

The Cordstead in Quebec: a BnB by Sandy and Angelika.

The Cordstead in Quebec: a BnB by Sandy and Angelika.

His banana tree produced 30 pounds of bananas!

His banana tree produced 30 pounds of bananas! Kinstone Cordwood Chapel in the springtime.

Kinstone Cordwood Chapel in the springtime.

John Meilahn, Copper Harbor, Michigan.

John Meilahn, Copper Harbor, Michigan.  Should you wish to learn how to build a cordwood cottage, cabin or home, please visit

Should you wish to learn how to build a cordwood cottage, cabin or home, please visit

“It’s around 12 feet square, we used lime mortar, the wood is softwood-larch and pine. It’s in the garden between 2 areas. Front door to enter, back to get to next bit (side to BBQ area). I haven’t totalled the cost-the cordwood was free, mortar not much, but the post and beam frame and roof were costly… could have been done with much smaller beams etc – we just went for chunky so it would last.”

“It’s around 12 feet square, we used lime mortar, the wood is softwood-larch and pine. It’s in the garden between 2 areas. Front door to enter, back to get to next bit (side to BBQ area). I haven’t totalled the cost-the cordwood was free, mortar not much, but the post and beam frame and roof were costly… could have been done with much smaller beams etc – we just went for chunky so it would last.” “We still have to render the blocks once we get a bit of decent weather. We are planning to insulate in between the beams, as we have found it retains heat well. We have electric and a radiator, so it could be used as an extra room to sleep in when the family all descend on us.”

“We still have to render the blocks once we get a bit of decent weather. We are planning to insulate in between the beams, as we have found it retains heat well. We have electric and a radiator, so it could be used as an extra room to sleep in when the family all descend on us.” It is a lovely place to sit, we have great views & it’s a perfect spot to watch the sunset.

It is a lovely place to sit, we have great views & it’s a perfect spot to watch the sunset. “We just used the lime mortar-there’s a lot of old stone buildings around us with thick walls, all done with lime mortar and they’re still standing and cool in the summer so we figured it would be fine.”

“We just used the lime mortar-there’s a lot of old stone buildings around us with thick walls, all done with lime mortar and they’re still standing and cool in the summer so we figured it would be fine.” “We cut and dried the wood in our polytunnel for around a year, and dipped each log in a borax solution before using. The mortar was easier, as we have a nearby supplier of lime mortar, which we mixed using your instructions for lime putty mortar. We used what they call an unhaired course mix and added a bit of argical as it’s pretty damp in Cornwall. We mixed it in a cement mixer a batch at a time and after a while learnt how much wall we could do per bucket of mortar.

“We cut and dried the wood in our polytunnel for around a year, and dipped each log in a borax solution before using. The mortar was easier, as we have a nearby supplier of lime mortar, which we mixed using your instructions for lime putty mortar. We used what they call an unhaired course mix and added a bit of argical as it’s pretty damp in Cornwall. We mixed it in a cement mixer a batch at a time and after a while learnt how much wall we could do per bucket of mortar. It was really good to have a range of shapes and sizes for filling awkward gaps but I often wanted little triangular ones and wood does not split into 4 evenly. (We ended up with a nice lot of kindling!) I would advise anyone attempting a build with a partner to be sure they have a good relationship, as we had quite a few heated ‘discussions’ during the process (but were always ready to tackle it again the next day)!

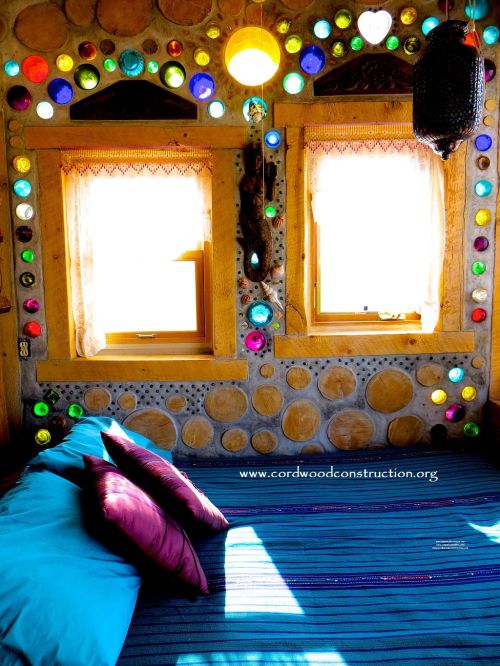

It was really good to have a range of shapes and sizes for filling awkward gaps but I often wanted little triangular ones and wood does not split into 4 evenly. (We ended up with a nice lot of kindling!) I would advise anyone attempting a build with a partner to be sure they have a good relationship, as we had quite a few heated ‘discussions’ during the process (but were always ready to tackle it again the next day)! We could only get green or clear bottles, so after cutting I painted the inside end with glass paint that is set by putting in an oven-a few didn’t take well, but the majority did and it’s nice to have some different colour in there.

We could only get green or clear bottles, so after cutting I painted the inside end with glass paint that is set by putting in an oven-a few didn’t take well, but the majority did and it’s nice to have some different colour in there. Baz writes, “Another pic of the inside…using an old sanding disc, I used friction to “scorch” the wood to darken and bring out the richness in the grain and also to protect the cordwood...this part of the UK it’s very damp so charing the ends of posts etc without using chemicals is not uncommon. We will see how that turns out in years to come… for fun, under the window is “hidden” a sailing ship for our gran kids to find,on other walls there are a clown and a cat…skirting boards are nearly finished and the white double doors are going back to wood…it’s been fun and thanks for the positive feedback…ocean apart, but same ideas …happy builds, Matey’s…”

Baz writes, “Another pic of the inside…using an old sanding disc, I used friction to “scorch” the wood to darken and bring out the richness in the grain and also to protect the cordwood...this part of the UK it’s very damp so charing the ends of posts etc without using chemicals is not uncommon. We will see how that turns out in years to come… for fun, under the window is “hidden” a sailing ship for our gran kids to find,on other walls there are a clown and a cat…skirting boards are nearly finished and the white double doors are going back to wood…it’s been fun and thanks for the positive feedback…ocean apart, but same ideas …happy builds, Matey’s…”

Floor plan for 1840 sq. ft. home (1,040 sq. ft. first floor, 800 sq. ft. second floor).

Floor plan for 1840 sq. ft. home (1,040 sq. ft. first floor, 800 sq. ft. second floor).

The hanging blue tubes (with metal receptacles) were very irritating to work around during construction. The masons were constantly bumping into them while mortaring.

The hanging blue tubes (with metal receptacles) were very irritating to work around during construction. The masons were constantly bumping into them while mortaring. The window boxes, door framing and wiring tubes are shown in the phot0. Notice that the window boxes are screwed into the top plate of the post and beam framework. This helps to assure that the windows will always open.

The window boxes, door framing and wiring tubes are shown in the phot0. Notice that the window boxes are screwed into the top plate of the post and beam framework. This helps to assure that the windows will always open.

We visited the home a year after completion to do any weatherizing that might be required We applied Permachinktm around a few log ends that had loosened and stuffed a few round log ends that had checked with white fiberglass. This well constructed home is easy to heat and blends beautifully into the surrounding woodland.

We visited the home a year after completion to do any weatherizing that might be required We applied Permachinktm around a few log ends that had loosened and stuffed a few round log ends that had checked with white fiberglass. This well constructed home is easy to heat and blends beautifully into the surrounding woodland.

Winter or summer, the White Earth Cordwood home is comfortable and inviting to family and friends.

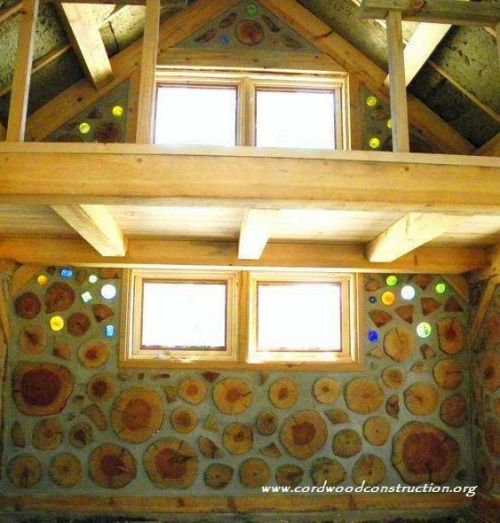

Winter or summer, the White Earth Cordwood home is comfortable and inviting to family and friends. (Above) Cedar, lime putty and glass bottles create a beautiful wall.

(Above) Cedar, lime putty and glass bottles create a beautiful wall. Inside is more forest (note the birch log) and a gorgeous masonry heater.

Inside is more forest (note the birch log) and a gorgeous masonry heater.  The main floor features an acid-etched floor, attractive random pattern cordwood and deep, plant-worthy window sills.

The main floor features an acid-etched floor, attractive random pattern cordwood and deep, plant-worthy window sills.  Unique and interesting wall accoutrements.

Unique and interesting wall accoutrements.

Their comment as they installed this solar panel array was “Sorry Coal!” Lots of subtle wit and wisdom on the always entertaining Nerdwood site.

Their comment as they installed this solar panel array was “Sorry Coal!” Lots of subtle wit and wisdom on the always entertaining Nerdwood site.

Western Red Cedar in a 30 year old cordwood home in British Columbia. The mortar joints are approximately one inch and the cordwood has all been split into unique and interesting shapes.

Western Red Cedar in a 30 year old cordwood home in British Columbia. The mortar joints are approximately one inch and the cordwood has all been split into unique and interesting shapes.  Above is a fine example of various shapes embedded in a mortar matrix.

Above is a fine example of various shapes embedded in a mortar matrix.  Ned Thilo used a brick framework with a random display in the center. He also used an off center crescent moon motif to create a work of art.

Ned Thilo used a brick framework with a random display in the center. He also used an off center crescent moon motif to create a work of art. As did Chelsea and Mark with their Alaskan sauna.

As did Chelsea and Mark with their Alaskan sauna.

Eric and Beth used rocks, bottles and a lightning bolt.

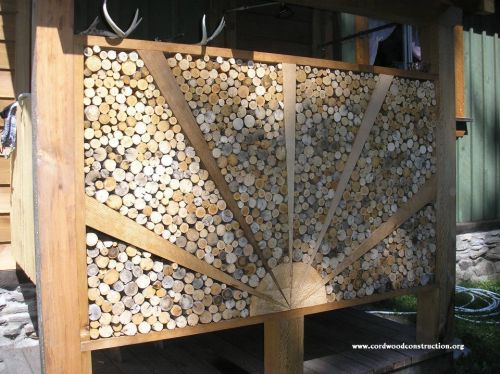

Eric and Beth used rocks, bottles and a lightning bolt.  Here deer antlers, bottles and marbles are used.

Here deer antlers, bottles and marbles are used.

Maranda is rightly proud of the work she (and others) did on the star wall at Kinstone.

Maranda is rightly proud of the work she (and others) did on the star wall at Kinstone. A sauna in Poland benefited from a very large, undulating piece of log and a red earthen mortar.

A sauna in Poland benefited from a very large, undulating piece of log and a red earthen mortar. Rounds and splits with 8 inch cordwood.

Rounds and splits with 8 inch cordwood.

Paying attention to and having many different sizes and shapes is incredibly helpful in creating your own piece of wall art. This process starts when you are splitting and stacking your wood for drying.

Paying attention to and having many different sizes and shapes is incredibly helpful in creating your own piece of wall art. This process starts when you are splitting and stacking your wood for drying.

The cabin rests in the middle of 320 acres of hardwood and conifer forest.

The cabin rests in the middle of 320 acres of hardwood and conifer forest.

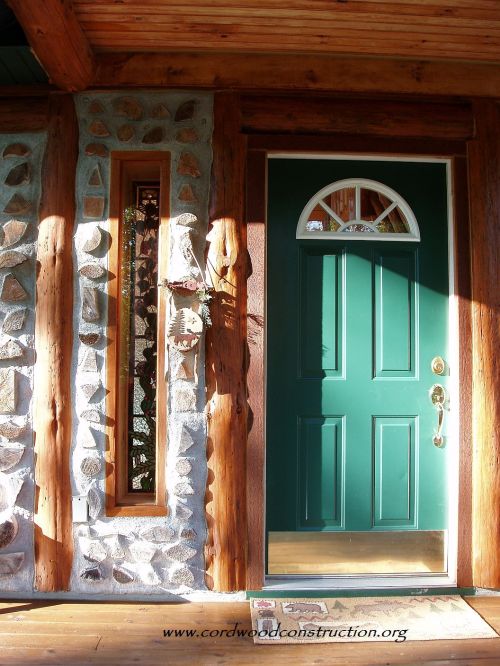

Cordwood Chalet in Golden, British Columbia

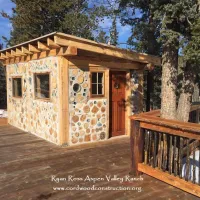

Cordwood Chalet in Golden, British Columbia This cottage shows how different building styles compliment one another: cordwood, lime plaster, cedar plank siding and stone, all take their turn showing off. In doing so, they make a truly unique cottage.

This cottage shows how different building styles compliment one another: cordwood, lime plaster, cedar plank siding and stone, all take their turn showing off. In doing so, they make a truly unique cottage. From the Airbnb site: “Situated in the stunning Blaeberry Valley, 15 minutes drive from Golden, our Cordwood Chalet is the perfect getaway to peacefulness and tranquillity in the heart of nature. Newly built and comfy, its location offers a wide range of outdoor activities.”

From the Airbnb site: “Situated in the stunning Blaeberry Valley, 15 minutes drive from Golden, our Cordwood Chalet is the perfect getaway to peacefulness and tranquillity in the heart of nature. Newly built and comfy, its location offers a wide range of outdoor activities.”  The covered porch, the curved railings and the green painted side doors blend with the cedar to give the building unmistakeable charm.

The covered porch, the curved railings and the green painted side doors blend with the cedar to give the building unmistakeable charm.  The nearby sauna is completed with the same attention to detail and the cordwood infill is done with clean mortar joints and attractive patterns.

The nearby sauna is completed with the same attention to detail and the cordwood infill is done with clean mortar joints and attractive patterns.  The side porch has an ingenious method of drying kindling for the wood stove. Here comes the sun!

The side porch has an ingenious method of drying kindling for the wood stove. Here comes the sun! It is quite evident that this building has a

It is quite evident that this building has a  Made from Western Red Cedar and Douglas Fir, this is a massive post and beam framed beauty with large overhangs.

Made from Western Red Cedar and Douglas Fir, this is a massive post and beam framed beauty with large overhangs.

A primary check will run right through the large rounds, from inside to outside and must be stuffed to prevent air and insect infiltration.

A primary check will run right through the large rounds, from inside to outside and must be stuffed to prevent air and insect infiltration.  Huge Douglas Fir posts make a sturdy statement.

Huge Douglas Fir posts make a sturdy statement.  These large pieces will continue to shrink in the wall, so caulking like Permachink or Log Jam (which comes in mortar colors) is important to have on hand.

These large pieces will continue to shrink in the wall, so caulking like Permachink or Log Jam (which comes in mortar colors) is important to have on hand.

This home was built in 1994. It is on the top of a hill and shows a wonderful view of the surrounding mountains and valley. It has 3 bedrooms and 2.5 baths and sits on 1.26 acres.

This home was built in 1994. It is on the top of a hill and shows a wonderful view of the surrounding mountains and valley. It has 3 bedrooms and 2.5 baths and sits on 1.26 acres.