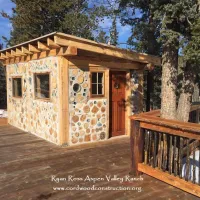

Alan Adolphsen built this absolutely beautiful small cordwood home in Hope, Maine in 2004. He describes his building adventure as an owner-builder. One with pluck and a good knowledge of construction. Here are a few words from Alan on how he decided upon cordwood and then tackled his project with gusto.

A corner section of wall with triangular split aspen pieces, which allowed for very precise mortar joints. Continue Reading about Alan’s amazing arches, stone foundation and hidden timber frame. Cordwood Construction

A corner section of wall with triangular split aspen pieces, which allowed for very precise mortar joints. Continue Reading about Alan’s amazing arches, stone foundation and hidden timber frame. Cordwood Construction

Nice work!

Great house, I plane to build a cordwood house in Arkansas.

I noticed it isn`t post and beam structure. How did you manage the roofing part?

Hi Mike, Let me add a photo to the post (go back in a few minutes) to show you. There is a hidden post and beam framework. Pretty sneaky, huh:0)

Why didn’t you use the walls for structural support of the roof?

Hi Ross,

Cordwood used to be built to hold up the roof. The problem was in two areas. 1. The mortar had to be strong enough to hold up the roof and because of this, it would dry to fast, crack mortar joints and separate from the log ends. Hence there was air infiltration and crummy looking walls. 2. The other problem was getting code approval in most areas. So the game plan switched and it became a best practice to use cordwood as infill with a simple post and beam framework. This meant the mortar could be weaker (a good thing) and not dry out so fast and there was much less mortar cracking and log loosening. We have developed a set of 14 best practices that we teach and encourage builders to use. Of course, these are not mandatory, but they are very helpful in getting a building permit. They are summarized in detail in the book Cordwood Construction Best Practices, which I wrote in 2012. Let me know if you have any more questions. +Richard Flatau

Have you had any of the wood cracking or splitting with moisture or extreme temperature changes. In the one photo you had a green sprayer, is it all sealed with something?

Thanks Dave

Hi David,

The green sprayer is a bleach water solution to keep the log faces from turning black. Aspen will do that when rain hits it. The wood needs to be peeled, split and dried before it is used. Usually for 2 years. That way it has done it’s cracking and splitting before being placed in the wall. The theory behind cordwood is that the log ends breath and transpire moisture. So they should never be sealed. However they can be stained on the exterior to keep a uniform color.

All the best,

Richard

sorry one more question… how did you work the insulation part of the build. Walls look plenty thick, but I wouldn’t think the R value of wood and mortar would be that high? Does the mortar sweat with diff. temperatures. I love your design, just curious on these few things. thanks

Hi David,

If the wall is 16″ then there is a 3″ mortar bead, 10″ of insulation and another 3″ mortar bead. The wood must be bone dry, the mortar slow setting (we use sawdust and lime) and the walls tuck pointed and covered for 7 days. The U of Manitoba tested the r-value of the walls at their engineering research facility in Winnipeg. They came up with 1.5 per inch of wall, so a 16″ wall is R-23.5. Here is a link to hundreds of photos of cordwood walls on my Cordwood Facebook page… http://www.facebook.com/cordwoodconstruction

Richard Flatau

Beautiful and looks like it’s well installated

Do you have any information regarding the flooring, electrical and plumbing?

Electrical is handled by either conduit or “jacketed/insulated” wire run inside the post and beam framework using wire staples. There are many pictures of electrical installations. It is actually very easy and code compliant.

Plumbing is done on the interior walls.

Electrical is handled by either conduit or “jacketed/insulated” wire run inside the post and beam framework using wire staples. There are many pictures of electrical installations. It is actually very easy and code compliant.

Plumbing is done on the interior walls.

Flooring is covered in 4 different posts on this blog. Use the search engine and type in Cordwood Flooring.

I love the house, & it was a great idea to build this way.